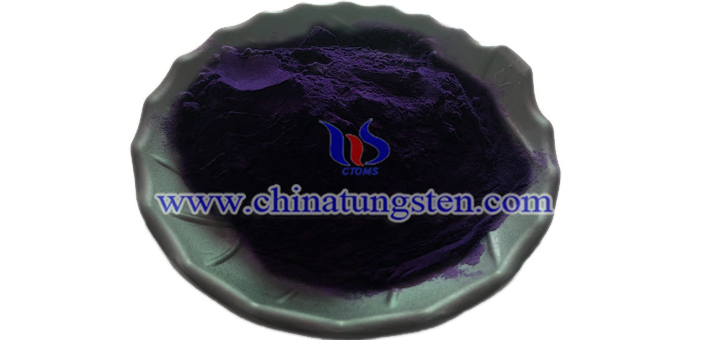

Violet tungsten oxide nano powder for manufacturing nano transparent heat insulating glass coating can be prepared by chemical vapor deposition (CVD) method. So, what is chemical vapor deposition?

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide.html

Chemical vapor deposition is a vacuum deposition method used to produce high quality, high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films. In typical CVD, the wafer (substrate) is exposed to one or more volatile precursors, which react and/or decompose on the substrate surface to produce the desired deposit. Frequently, volatile by-products are also produced, which are removed by gas flow through the reaction chamber. And the xperiments are usually carried out in a closed container to avoid interference with impurities. Microfabrication processes widely use CVD to deposit materials in various forms, including: monocrystalline, polycrystalline, amorphous, and epitaxial. Other than tungsten, materials include silicon (dioxide, carbide, nitride, oxynitride), carbon (fiber, nanofibers, nanotubes, diamond and graphene), fluorocarbons, filaments, titanium nitride and various high-k dielectrics.