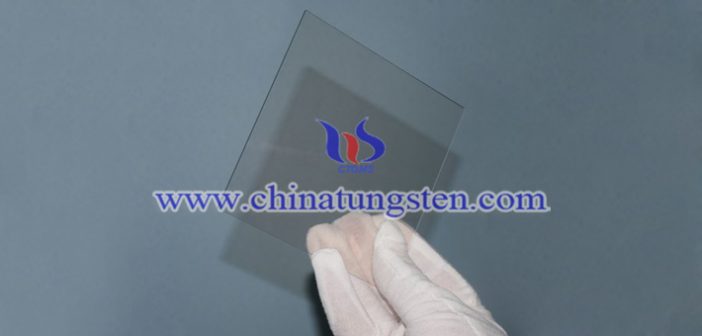

Tungsten trioxide film is an electrochromic film, which can be prepared on the FTO transparent conducting glass. According to reports, in order to study the effect of film thickness on the structure and electrochromic properties, metal tungsten with a purity of 99.95% was used as a target, and a WO3 film was deposited by magnetron sputtering on a FTO conductive glass substrate using a coater under the condition of pulse direct current power source reaction.

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide.html

In this process, what should be noted is that FTO conductive glass is used as the substrate, which needs to be cleaned thoroughly. After washing away the dust on the surface of the substrate glass with clean water, clean the grease with detergent and acetic acid, then rinse it with deionized water, and finally blow off the residual moisture with high-pressure dry nitrogen. Experts prepared tungsten oxide films of different thicknesses such as 50nm, 100nm, 150nm, 200nm, 250nm, and 300nm by controlling the rate of substrate movement and the number of back and forth movements under the cathode.