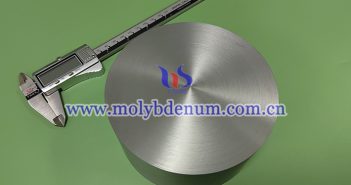

TZM molybdenum alloy is a high-performance alloy based on molybdenum, with small amounts of titanium (Ti), zirconium (Zr), and carbon (C) added. Its name derives from the initials of these additive elements. As an advanced material widely used in aerospace, nuclear industries, and high-temperature industrial applications, TZM alloy is renowned for its exceptional melting point and high-temperature performance. Molybdenum itself is a high-melting-point metal, with a melting point of 2623°C. The melting point of TZM molybdenum alloy, enhanced by the…