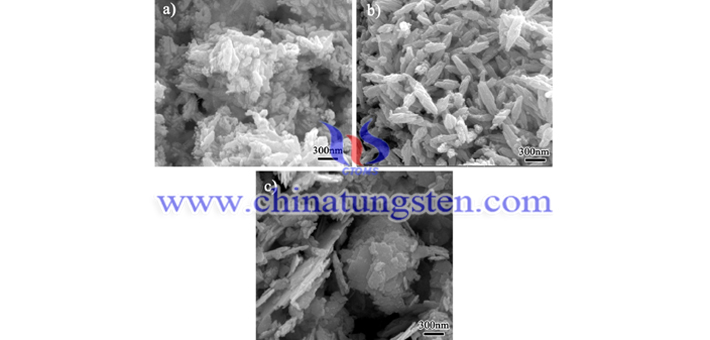

Morphology of tungsten oxide nanoparticles will affect the performance of the prepared energy saving glass coating. In this regard, some experts have studied the effect of reaction temperature on the morphology of the tungsten oxide nanopowder. Experts adopted solvothermal method to prepare tungsten oxide nano powder using n-propanol as the alcohol solvent. Wherein, the molar concentration of the solution was 15mM, the reaction time was 24h, and the reaction temperature was 180°C (a), 200°C (b), and 220°C (c), respectively, in the figure. The SEM image of the tungsten oxide particles at different temperatures is shown below.

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide.html

As can be seen from the figure, at a temperature of 180°C, the tungsten oxide nano particles are stacked on each other to form a random block-like area. When the reaction temperature is raised to 200°C, the tungsten oxide nano particles grow into spindle-shaped nanorods with a length of about 300nm-500nm, a cross-sectional diameter of about 150nm. These nanoparticles have good dispersion and size uniformity. There is a longitudinal dent on the surface of the nanorods. It is presumed that the nanorod particles are formed by the longitudinal aggregation of finer nanorod particles. When the reaction temperature is raised to 220°C, the tungsten oxide nano particles are in the form of flakes. The thickness of the nanosheet is between several nanometers and several tens of nanometers, the width is between several hundred nanometers and several micrometers, and a part of the nanosheets are stacked to form nanosphere particles with a diameter of about 500nm.