Composite tungsten electrode materials can be categorized into thorium-tungsten electrodes, cerium-tungsten electrodes, yttrium-tungsten electrodes, zirconium-tungsten electrodes, and lanthanum-tungsten electrodes, depending on the additives used. Although all these tungsten electrodes are primarily made from the refractory metal tungsten, their physical and chemical properties and applications vary slightly due to differences in modifiers.

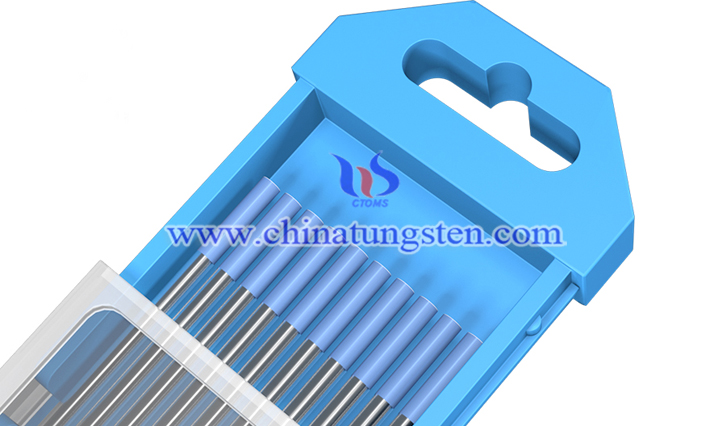

Taking the lanthanum-tungsten electrode as an example, it is an electrode product with an appropriate amount of lanthanum oxide added to a tungsten base, known in English as the Lanthanum tungsten electrode. It is often used as a substitute for thorium-tungsten electrodes. Depending on the lanthanum oxide doping level, the color-coded tips of lanthanum-tungsten electrodes differ: electrodes with 0.8-1.2% (WL10) are marked black, those with 1.3-1.7% (WL15) are gold-yellow, and those with 1.8-2.2% (WL20) are sky-blue. Research indicates that lanthanum oxide, with its low electron work function, easy arc initiation, and lower tip temperature, significantly enhances the service life of lanthanum-tungsten electrodes.

In terms of physicochemical properties, lanthanum-tungsten electrodes combine the characteristics of metallic tungsten and lanthanum oxide, featuring no radiation, low evaporation rate, excellent arc initiation, high arc column stability, good ductility, superior erosion resistance, and excellent mechanical cutting performance. Notably, a lanthanum-tungsten material with 1.5% content has conductivity close to that of a 2% thorium-tungsten electrode.

Regarding production processes, the preparation of lanthanum-tungsten materials involves: first mixing lanthanum acetate, ammonium paratungstate, tungsten trioxide, and tungsten powder, then adding water to create lanthanum-tungsten coating powder; the decomposition of lanthanum salts in this coating powder occurs in a hydrogen atmosphere.

In terms of applications, lanthanum-tungsten electrodes are suitable for both direct current (DC) and alternating current (AC) welding.