Tungsten alloy collimators, in competition with lead collimators in the field of radiation control, have gradually become the mainstream choice due to their unique composition and performance advantages. In terms of composition, tungsten alloy collimators use tungsten as the base, typically alloyed with elements such as nickel, iron, and copper to form alloys like tungsten-nickel-iron or tungsten-nickel-copper, with tungsten content reaching over 90%. This composition provides high density, high strength, and good processability. In contrast, lead collimators are mainly made of pure lead or lead-antimony alloys, where antimony enhances mechanical strength, but the material remains relatively soft overall.

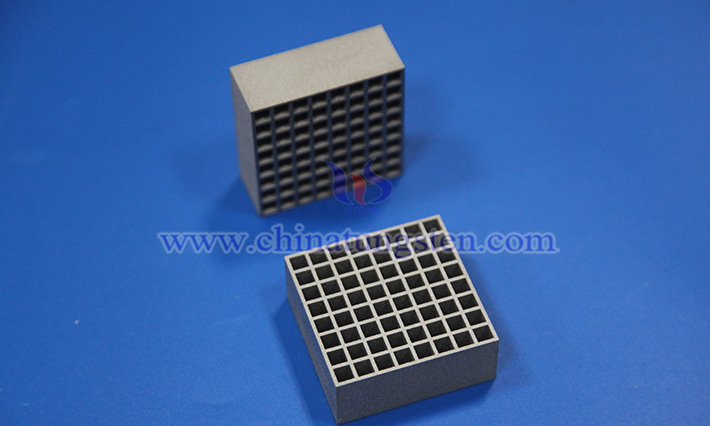

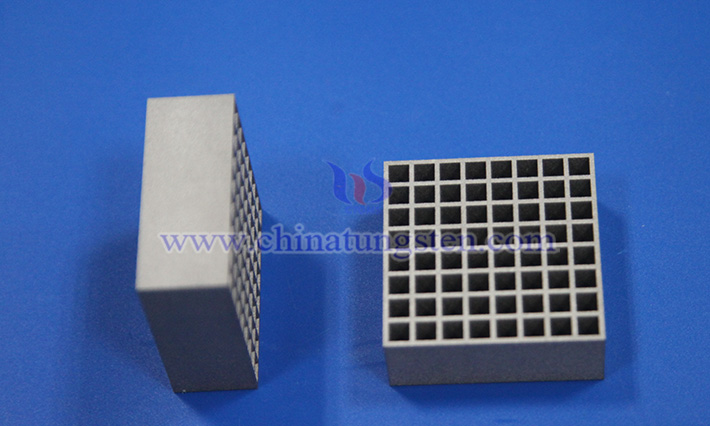

The difference in radiation shielding efficiency stems from the high-density characteristic of tungsten alloys. The density of tungsten alloys is approximately 16.5-18.75 g/cm3, higher than lead's density. According to the principle of radiation attenuation, the higher the material density, the stronger its ability to block gamma rays and X-rays. For the same shielding effect, the thickness of tungsten alloy collimators is smaller. This "thinning" advantage is particularly critical in space-limited applications, such as portable radiotherapy devices in the medical field or small detection equipment for industrial flaw detection, significantly reducing equipment volume and improving operational flexibility.

Differences in mechanical properties affect the service life and processing precision of collimators. Tungsten alloys offer excellent impact resistance and wear resistance, making them resistant to deformation or damage during long-term use or frequent adjustments. Lead, however, has lower tensile strength and hardness, prone to dents from external collisions or even gradual deformation under its own weight, leading to ray channel shifts and affecting control precision.

Environmental friendliness is a more notable advantage of tungsten alloy collimators. Lead is a heavy metal, and lead ions can enter the human body through respiratory or skin contact. Once inside, lead ions accumulate gradually, potentially damaging the nervous system, kidneys, and hematopoietic system. In contrast, the constituent elements of tungsten alloys are mostly low-toxicity or non-toxic, such as tungsten, nickel, and iron, which have relatively stable properties in nature and do not produce toxic ions under normal conditions. Even after disposal, tungsten alloy collimators can typically be processed through conventional alloy recycling methods, with a smaller environmental impact compared to lead alloys.

In terms of heat resistance and chemical stability, tungsten alloys have a higher melting point, maintaining structural stability in environments where high-energy rays cause localized temperature increases over prolonged exposure. Lead alloys, with a lower melting point, may soften or melt under prolonged high temperatures. Regarding chemical stability, tungsten alloys resist corrosion in humid, acid-base environments, making them suitable for nuclear waste management. Lead alloys react with oxygen and carbon dioxide in the air to form loose oxide layers, leading to surface peeling and impacting shielding performance.

From an overall cost perspective, although the initial procurement cost of tungsten alloy collimators is higher than lead alloys, considering factors such as longer service life, lower maintenance frequency, and reduced environmental processing costs, the long-term usage cost is lower, making them particularly suitable for applications with high demands for safety and durability.